DIY Guide for Taping and Coating a Drywall Butt Joint

When it comes to drywall installation, one of the trickiest aspects is dealing with drywall butt joints.

These joints occur when the edge of one drywall sheet butts up against another, creating a visible seam.

After years of finishing drywall, I can tell you that butt joints separate the beginners from the pros.

Most people struggle with these tricky seams, but with the right approach, you can get professional results.

Here, I will take you through everything you need to know about taping and smoothing butt joints, using tools and techniques that give you a professional finish every time.

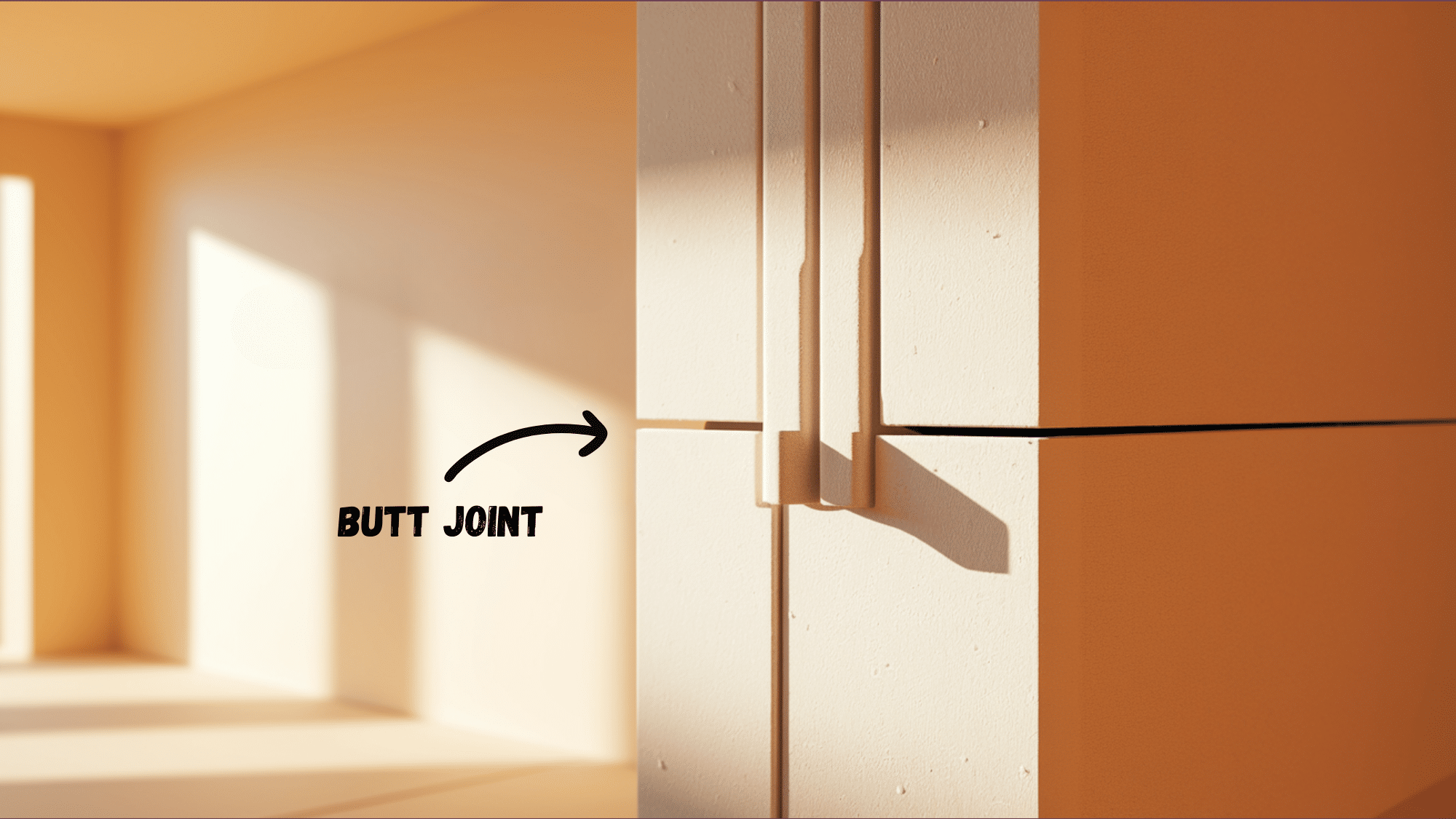

What is a Drywall Butt Joint?

A drywall butt joint is the visible seam created when the edge of one drywall sheet meets another without the tapered edge typically seen in other joints.

This creates a challenge. When you apply tape and compound, the joint becomes raised above the surrounding wall surface.

The goal is to feather this raised area so it blends smoothly. Butt joints require extra care with joint compound to ensure a smooth, even surface.

You’ll find butt joints wherever drywall sheets don’t align with tapered edges. They’re common on ceilings and walls where space limitations force you to use partial sheets.

Tools and Materials Required for Drywall Butt Joints

Here’s a list of tools and materials you’ll need to get the job done right and achieve a professional-like finish with ease.

Tools

- 6-inch and 12-inch drywall knives

- Mud pan

- Drywall tape (paper or fiberglass)

- Utility knife

- Sanding block or pole sander

Materials

Step-by-Step Guide for Taping and Coating the Butt Joint

Here’s a step-by-step process to guide you through the complete process in order to achieve a smooth, professional finish on your drywall project.

Step 1: Prepare the Area

Make sure your drywall sheets are secure and the edges are clean.

If needed, trim the edges with a utility knife to ensure the surface is straight and flush. Proper preparation reduces the chance of gaps or uneven seams.

Step 2: Apply Joint Compound

Using a 6-inch drywall knife, apply a thin layer of joint compound over the butt joint.

Make sure the compound is spread evenly, covering the joint fully.

Don’t apply too much, it’s better to start with thin coats.

Step 3: Apply the Drywall Tape

Press drywall tape over the compound while it’s still wet. Use paper tape for better adhesion and durability.

Smooth the tape into the compound using your drywall knife, ensuring no air bubbles remain.

Step 4: Apply Additional Coats of Compound

After the first coat dries, apply a second coat of joint compound.

Use a 12-inch knife to spread the compound, feathering the edges to blend the joint into the surrounding wall.

Let it dry before sanding it smooth. Repeat with a third coat for the best finish.

Step 5: Sand the Joint

Once the final coat has dried completely, lightly sand the joint using a sanding block or pole sander.

Sanding smooths out any bumps and helps blend the joint with the rest of the wall.

Take your time here, as proper sanding is key to a flawless finish.

Step 6: Prime and Paint

Apply a coat of primer to the joint to seal the compound and prepare the wall for painting.

Once the primer dries, paint the wall with your chosen color.

The butt joint should now blend in seamlessly with the rest of the drywall.

Essential Tips and Safety Precautions for Perfect Butt Joints

Working with drywall butt joints requires the right technique and safety measures to get professional results.

Here are the key points to keep in mind:

- Use a 12-Inch Drywall Knife for Final Coats: This spreads compound evenly and creates the smoothest possible finish

- Feather Edges Progressively Wider: Make each coat extend further than the last to blend seamlessly into the wall.

- Always Wear a Dust Mask when Sanding: Protect your lungs from harmful dust particles during the sanding process.

- Let Each Coat Dry Completely: Rushing between coats leads to cracking and poor adhesion that ruins your work.

- Sand Lightly and Carefully: Too much pressure can damage the surrounding drywall and create an uneven surface.

- Embed the Tape Properly in The Compound: Smooth the tape with your knife to prevent bubbles and blisters from forming.

How to Maintain the Coating for a Long Time?

Don’t worry, keeping your drywall joints looking great isn’t complicated at all!

A good primer before painting will seal everything nicely and help prevent those annoying little cracks from showing up later.

Go with quality paint in semi-gloss or satin since it cleans easily and lasts longer.

Just keep moisture levels reasonable with decent ventilation, and maybe grab a dehumidifier if your home gets too humid.

It’s smart to save some leftover paint and compound for those tiny touch-ups that might pop up over time.

Be gentle around the joint areas, and you’ll be amazed at how long your smooth walls stay looking perfect.

Estimated Budget: DIY vs Professional

Here’s a detailed breakdown to help you make the best choice for your budget:

| ITEM/SERVICE | DIY COST | PROFESSIONAL COST | NOTES |

|---|---|---|---|

| Joint Compound | $10 – $20 per bucket | Included in service | DIY requires purchasing; pros usually include labor |

| Drywall Tape | $3 – $10 per roll | Included in service | Paper or mesh tape options for DIY |

| Drywall Knives Set | $10 – $30 | Not needed | 6″, 10″, 12″ knives recommended for DIY |

| Mud Pan | $5 – $15 | Not needed | Essential tool for holding compound |

| Sanding Tools | $10 – $50 | Not needed | Includes sandpaper, sanding blocks, or electric sanders |

| Primer | $15 – $30 per gallon | $100 – $200 (materials) | High-quality primer essential for both approaches |

| Paint | $20 – $50 per gallon | Included above | Semi-gloss or satin recommended |

| Labor | Your time (20-40 hours) | $40 – $75 per hour | Professional labor rates vary by location |

| Total Cost | $73 – $205 | $300 – $700+ | DIY assumes no existing tools; professional includes everything |

Note: These prices can vary significantly based on your location, project size, and material quality. DIY costs assume you’re starting without tools, while professional estimates may be higher for complex jobs or premium finishes.

Brand Recommendations

If I were to recommend, I would like you to refer to the list below:

- Joint Compound: USG (Sheetrock), ProForm, CertainTeed, DAP

- Primer:Benjamin Moore, Zinsser (Rust-Oleum), KILZ, USG (Sheetrock)

- Paint:Benjamin Moore, Sherwin-Williams, Behr, Valspar

PS: It’s not sponsored, they’re just good recommendations

Let’s Wrap It Up

Mastering butt joints takes practice, but these techniques will get you professional results.

Start with less visible areas to build your skills before tackling the main walls.

With patience and the right tools, you will achieve a professional-looking finish every time.

It’s about following the steps carefully.

Remember, buddy, patience is key.

Rushing through coats or skipping drying time always shows in the final result.